Meltio – Blue Lasers for Laser Wire Deposition

With the recent growth in the adoption of laser wire deposition systems and the parallel technological advancements in shorter wavelength direct diode lasers, the second generation of Laser wire ded systems from Meltio are built on custom process-specific blue laser systems to print metal parts more efficiently and from a larger range of materials. Starting with the Meltio M600.

Benefits of Blue Lasers

In Wire-DED processes, high-power lasers are used to melt and deposit wire filler material. The use of blue lasers offers numerous advantages over conventional near-infrared lasers in this application.

As blue light is absorbed more effectively by most metals compared to Near Infrared (NIR) light, reducing the wavelength from 980 to 450 nm means that a higher fraction of the laser energy is used to heat up and melt the metal, leading to faster deposition at the same laser power and an overall reduced energy consumption per part – a critical parameter especially as industrial adoption of these systems increases and every ounce of material within a 3D print must be brought to its melting point by the laser energy. Pollution and emissions of these processes are directly related to the laser systems’ energy efficiency.

Increasing the energy efficiency of and utilizing energy-efficient additive manufacturing processes such as laser wire deposition reduces the environmental impact of the manufacturing sector.

This effect is amplified particularly with reflective materials such as Aluminium and Copper alloys, which are in high demand and exceedingly difficult to process with conventional lasers in the Near Infrared domain.

Blue Laser Limitations

Despite their numerous advantages however, blue lasers are still a rare sight in the additive manufacturing space, as the cost of blue lasers is typically several hundred per cent higher than that of an equivalent NIR source. This disadvantage is compounded by the fact that most Laser wire deposition heads are designed around high power fiber coupled lasers, as a significant part of the higher cost of blue lasers is related directly to the difficult alignment and fiber coupling processes that allow for the creation of kW class blue lasers.

Tackling the limitations: the birth of a new system

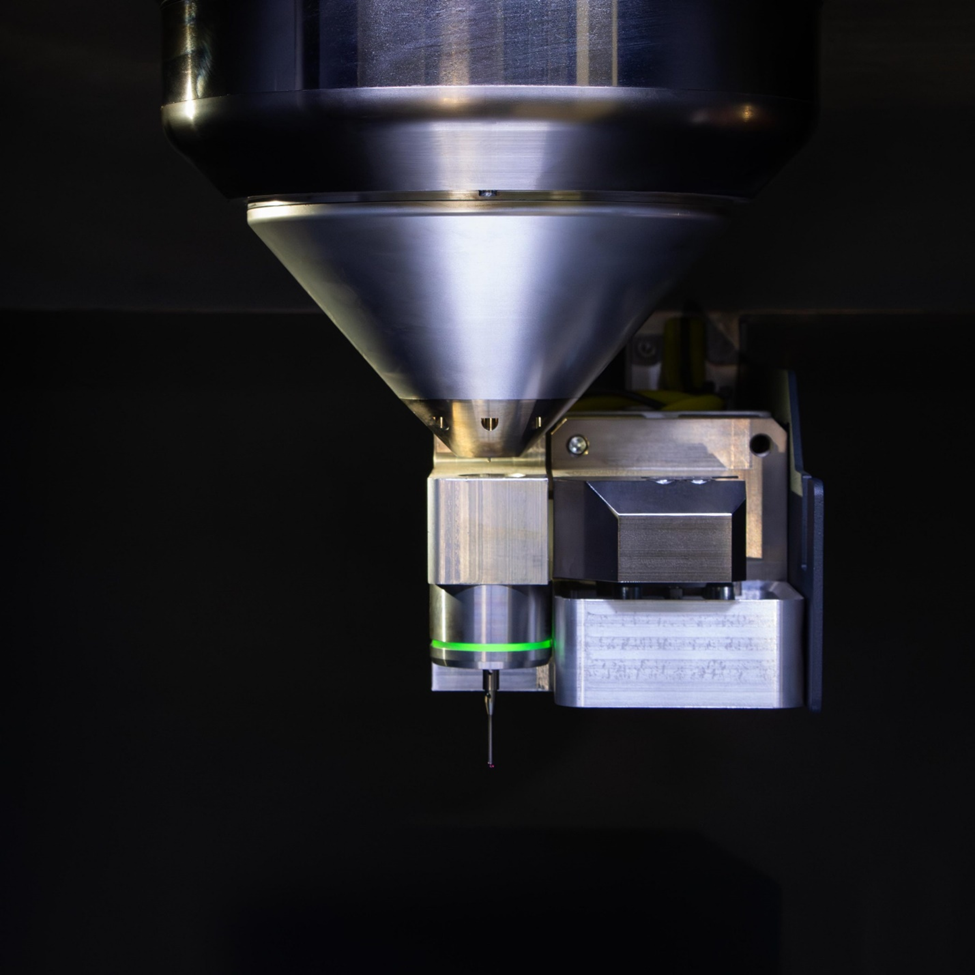

As our main driver is the large-scale industrial adoption of laser wire additive manufacturing, we could not afford to simply purchase different laser sources and fiber-couple them into our existing deposition head. Instead, over the past three years, we have worked on a new device that directly integrates the blue laser sources into the processing head, while bringing more manufacturing steps in-house to improve performance and flexibility while reducing cost.

Through insourcing these processes, we were able to tailor-make a laser source that perfectly suits the needs of Laser Wire Additive manufacturing, requires fewer optical elements and delivers a higher wall-plug efficiency than one would expect in blue laser sources.

Integrating the lasers into the deposition head brings another benefit as it concentrates all optical assemblies in a single sealed subassembly without the need to disconnect fragile fiber optics during maintenance on the system.

Lastly, the biggest benefit of building our laser system from the ground up was that we were able to remove the necessity for manual laser-wire alignment. Aligning the focal spots of the laser to the wire is traditionally a manual process that introduces variance between set-ups and requires additional operator training.

By varying the energy distribution and improving the wire guiding precision we are now able to offer a factory-aligned deposition head that does not require realignment once in service and tolerates the slight variances between different materials.

TIP: Download the spec sheet to know more about the Meltio M600 system.

Conclusion

In summary, by developing a laser source directly with laser wire deposition in mind we are delivering a system that requires less operator interaction, uses less energy and maintains a highly competitive price.

And while the development of the laser system and corresponding manufacturing system was a complex yet rewarding learning experience for us (involving the installation of clean rooms, manufacturing expertise and thousands of testing hours) we believe that the development of process specific laser sources is a requirement for laser wire deposition to take a foothold in the manufacturing industry which demands ever increasing performance and reliability while reducing the carbon footprint of the final product.