Main Menu

Types

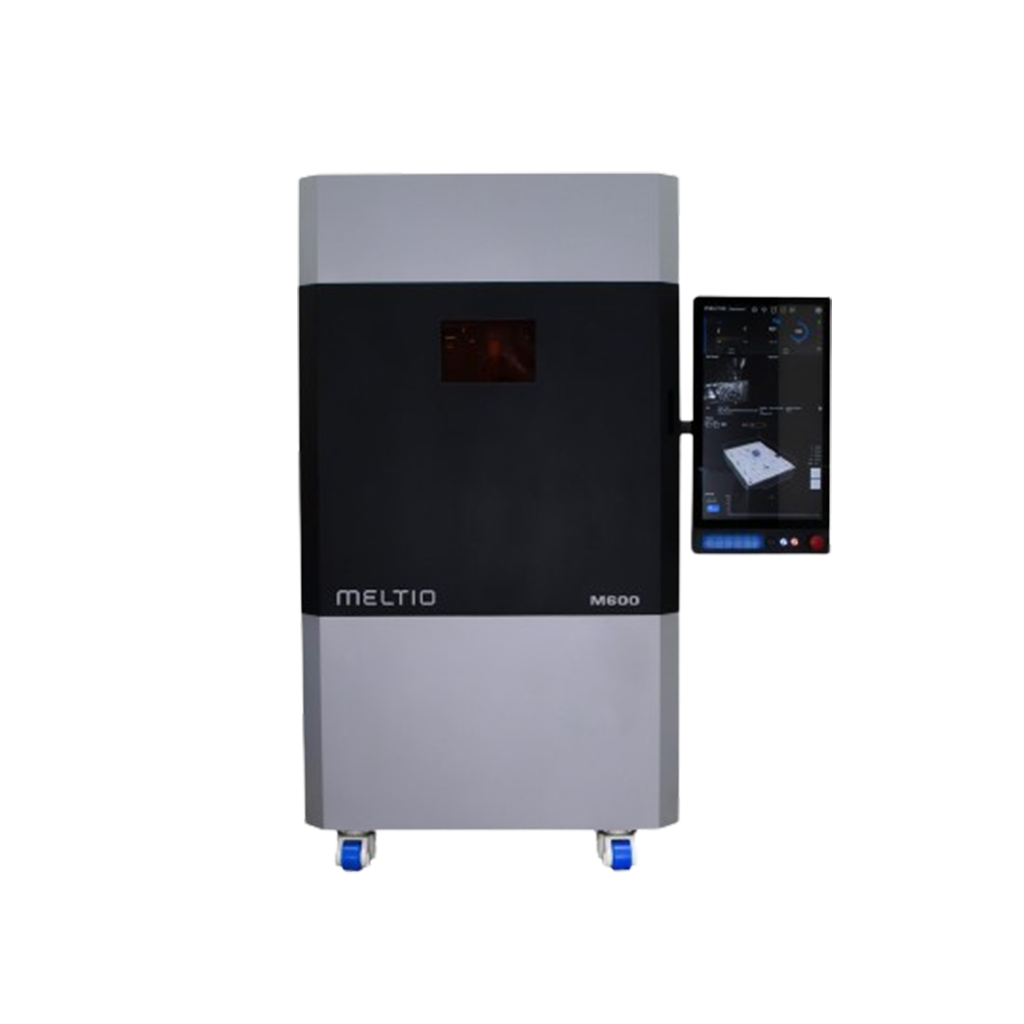

Metal 3D Printer

Innovative metal additive manufacturing technology offers comprehensive support for a variety of high-performance metal materials, ensuring versatility and reliability in metal 3D printing. From stainless steel and aluminum to titanium and nickel alloys, this advanced technology accommodates diverse material requirements. With the capability to produce unique, robust, and lightweight parts tailored for complex industrial applications, metal additive manufacturing is revolutionizing manufacturing processes across industries.

LMD (Laser Metal Deposition)

Laser Metal Deposition (LMD) wire printing is an additive manufacturing method where metal wire serves as the feedstock instead of powder. A high-powered laser melts the wire as it’s fed onto a substrate, forming molten pools that solidify to create the object layer by layer. This technique enables rapid fabrication of metal components with high precision, suitable for repairing existing parts or manufacturing intricate geometries efficiently.

FFF (Fused Filament Fabrication)

Metal-bonded Fused Filament Fabrication (FFF) uses a composite filament of metal powders and polymer binder. After printing, the part undergoes debinding, where the polymer is removed, leaving behind a porous metal structure. This is typically achieved through thermal or chemical processes. Following debinding, the part is sintered, a high-temperature process that fuses the metal particles together, enhancing strength and density. Both steps are crucial for achieving the final metal properties and structural integrity of the printed part.

PRECISE 3D Hub

DIRC Warehouse, W4-D1 Dubai Investment Park - 2, Dubai - United Arab Emirates

sales2.solution@preciseme.com

Contact Number

+971 54 307 2749